The Demanding Off-Hour Escapes of China’s High-Tech Workers

By DAN LEVIN

Published: July 16, 2013

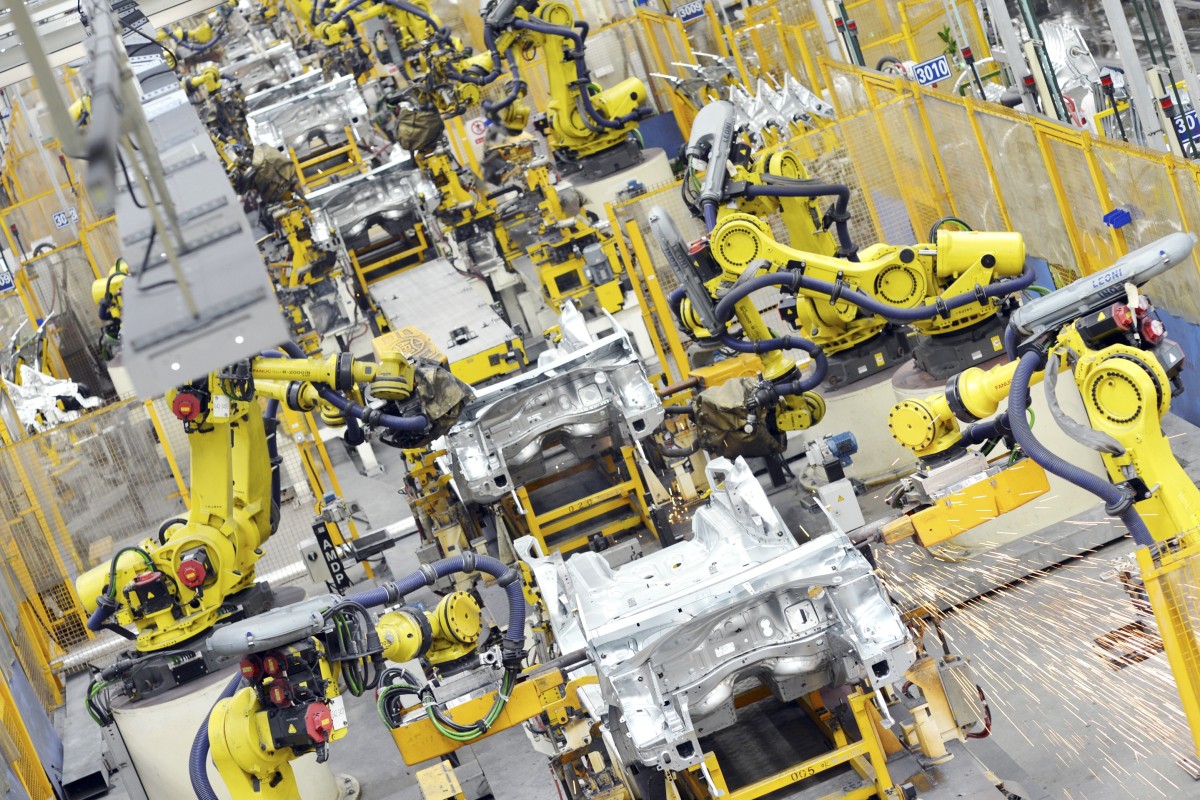

Thousands of young Chinese come to the city of Zhengzhou to work in electronics factories. To escape the monotony of the assembly line, many take up roller skating as a hobby, like at the outdoor roller rink. More Photos »

Liang Yulong, 19, who tests iPhone motherboards at the Foxconn Zhengzhou Technology Park, arrived at the club with a single goal in mind: to obliterate his dreary daytime reality on the spring-loaded dance floor. “Dancing lets me vent my anger and stress,” he said, cigarette in hand. “When I’m here, I forget everything else.”

Here on the gritty outskirts of Zhengzhou, the capital of central Henan Province, the nocturnal menagerie reveals a little-explored aspect of the global supply chain, the off-hour escapes that give the masses of workers the motivation to return to the assembly line.

The hands that make the world’s electronics belong almost entirely to young people with dreams of their own, and a lifetime of contented industrial drudgery is not among them. Their precious time off is a rare chance to enjoy the present as they strive for a better future.

“Everyone gets psyched for the weekend,” said Bai Sihai, 24, as he navigated open potholes on the way back to his dorm after work one afternoon. His plan? A video-game binge session at an Internet cafe followed by a long-distance phone call to his girlfriend.

The captains of industry are beginning to see the merits of off-hours leisure. In recent years, a wave of riots and suicides at China’s huge factories have drawn attention to working conditions. In April and May, two workers and a prospective employee jumped to their deaths from dormitories that cater to workers at the Zhengzhou plant, which is owned by Foxconn, the Taiwan-based manufacturing giant that produces electronics for Apple, Microsoft and other companies. Foxconn maintains that the suicides were unconnected to work at the factory. Also in May, a worker committed suicide at a Samsung plant in the southern province of Guangdong, where labor rights organizations had documented a string of violations like forced overtime and under-age workers.

The industry has responded with carrots and sticks to save both the lives of their workers and their own corporate reputations. Under pressure, Foxconn has raised wages and cut overtime hours. At the Shanghai plant run by Quanta, which makes hardware for companies including Apple, Toshiba and Asus, workers can pay for yoga and taekwondo classes.

After the latest suicides at the Zhengzhou plant, the company instituted “silent mode,” which banned all talk about nonwork tasks on the factory floor. Although Foxconn later announced it had rescinded the policy after a public outcry, workers say it remains in effect.

In the high-tech Olympus of Silicon Valley, employees in ergonomically luxuriant offices can get subsidized massages and haircuts, scale rock-climbing walls, play foosball, meditate and do Pilates — all in the name of promoting creative innovation.

The work environment is considerably more bare-bones here. Unlike Apple’s modernistic new campus in Cupertino, Calif., which will be surrounded by apricot trees, the Zhengzhou factory has all the charm of a penal colony. Employees, who must wear matching uniforms, say supervisors routinely curse and yell. In the residential compounds, rows of brick dormitories house up to eight workers in rooms filled with metal bunk beds, a combination shower-toilet, and not much else.

Perhaps that is why the world beyond the factory gates resembles a gigantic street fair. As dusk fell one night recently in Zhengzhou, Mandarin pop music blared from hair salons and couples strolled past stalls selling pirated DVDs, sliced watermelon and roses covered in silver glitter. A flatbed truck piled high with oversize stuffed animals drew a mob of young women like sharks to blood. “I want the green teddy bear,” cooed a teenage girl to her boyfriend, who dutifully handed over 10 renminbi, or $1.60.

Down the block, a construction site played host to a parade of distractions, including a tattoo parlor set up in the back of a van, those arcade games with the metal claw that featured a pack of cigarettes as the big prize and a beer garden of sorts, where hordes of young factory workers chugged watery beer and chain-smoked over plates of sliced pig knuckles.

At some point, a troupe of dolled-up singers was supposed to take the nearby stage, though Luo Haojie, 20, and his friends were finding ample amusement in their shot glasses. In May, Mr. Luo quit his factory job making iPhone 5 parts, which earned him about $295 a month, including overtime. “Our supervisors are vicious,” and the cafeteria food is terrible, he said, to a round of applause from his drinking buddies.

Eventually he will need to find another job, but for now he is content to bask in the joys of youth, which means meeting girls and getting drunk with his former co-workers. “I’m here for my bros,” he said. “Without them I’d be miserable.”

Summer is the low season in China’s factory towns, so many workers get a day off on weekends, sometimes even two. There are numerous colorful characters on hand to keep them entertained. One evening, a band of itinerant performers dressed like Buddhist monks had set up shop across from a KFC-inspired eatery confusingly named Donut. Garbed in silken yellow robes, the “celebrity acrobatic snake-training talent team” worked the crowd of bored onlookers by whipping balloons and hawking blessed ornaments for rearview-mirrors. A monk with an earring blew fireballs.

“The circus that came around a few months ago was better,” said Li Yu, 19. “They had real lions and tigers.”

Those looking for more athletic diversions can usually be found at the local roller rink.

In the glow of swirling rainbow lights one Saturday, Zhou Pengzheng, 20, another iPhone 5 motherboard tester, narrowly avoided several neophytes as he spun to a halt on a pair of $160 in-line skates, which cost him roughly a third of his monthly salary. “It feels like I’m flying,” he said, before zooming once more into the throng of careening youths on tiny wheels.

In-line and roller skating has developed something of a cult following among the Foxconn strivers. A half dozen teams with names like Rainbow, F-2 and Shadow gather for weekly group skating sessions across the city.

Fang Xuema, 17, learned to skate not long after coming to work at Foxconn last spring and soon joined team Shadow, which has around 100 members. The rink has since become her second home. A high school dropout, she quit the factory in May, because her age prohibited her from working lucrative overtime hours. “I used to come to the rink twice a week, but now I’m here every night,” said Ms. Fang, in a black miniskirt and matching nail polish.

At 11 p.m., the street performers had vanished and the love hotels were getting busy. After a long day of making iPhones, Wang Puyan, 20, and his girlfriend were heading toward their rented apartment off-campus, since factory dormitories are separated by gender.

A romantic adventure was not in the cards, however. “We see each other every day at work,” he said. “Why would we go on a date?”

Reply With Quote

Reply With Quote

:format(webp)/cdn.vox-cdn.com/uploads/chorus_image/image/55557845/pexels_photo.0.jpg)